Products

gas and oil installations, MEBA measurings...

Service program

service, calibration, CNC turning, milling...

Sales program

Leser, Danfoss, Bopp&Reuther...

Contact information

SPECIJALNA OPREMA - Lučko d.o.o.

Dolenica 20, Donji Stupnik, 10250 Lučko

ZAGREB, HRVATSKA

POSLOVNA JEDINICA JUŽNA HRVATSKA

Ivana Pavla II 19a, 21212 Kaštel Sućurac,

SPLIT, HRVATSKA

Email: specijalna-oprema@specijalna-oprema.hr

Phone: +385 (0)1 653 0671, +385 (0)1 653 0677

Fax: +385 (0)1 653 0680

The PDF document below provides detailed information for this product

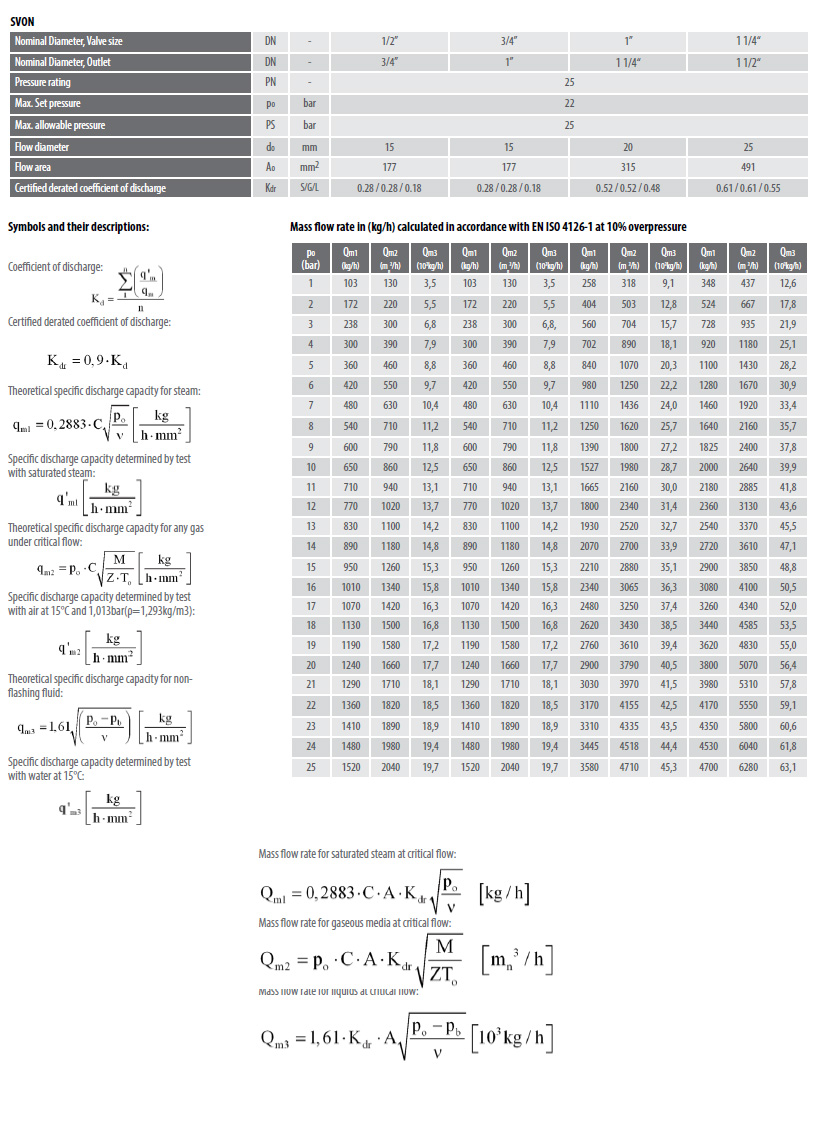

DN 1/2” - 1 1/2”

PN 25

p 1 - 25 bar

t -20°C / +180°C

acceptable media oil, petrol, natural gas, water, steam, LPG

connections ISO 7-1, ANSI B1 20.1

APPLICATION

Safety relief valve SVON is used for relieving pressure of system in which is being installed. It’s simplicity and reliability makes it perfect safety valve for almost every system or fluid.

Accuracy and valve performance stays permanent even on heavy duty demands. Due to simple design makes it easy to perform service and calibration.

DESIGN FEATURES

“Safety relief valve SVON is angled type of valve, with thread end connection for exhaust pipeline. It automatically opens and relief limited volume of gas, and automatically closes when pressure normalizes in the system it secures.”

“Safety valve acts directly according to the developed force, as a result of gas pressure on the plate the set force of the spring is resised. With the adequate increase of pressure, the seat is lifted up to max. 1/4 seat diameter and with this the exiting

conduit is opened.”

ON REQUEST:

- special ”PP” design for back pressure applications

- connections specified by customer

- every part can be produce to meet customer specification requirements

- special modification for aggressive media

TESTING & CALIBRATION

EN ISO/IEC 17025 certified laboratory

APPLIED STANDARDS, CODES & DIRECTIVES

EN ISO 4126-1 “Safety devices for protection against excessive pressure. Safety valves”

EN 12516-3 “Valves-Shell design strenght. Experimental method”

EN 13463-1 “Non-electrical equipment for use in potentially explosive atmospheres. Basic method and requirements”

EN 13463-5 “Non-electrical equipment for use in potentially explosive atmospheres. Protection by constructional safety ‘c’ “

94/9 EC (ATEX) “Equipment and protective systems intended for use in potentially explosive atmospheres”

97/23 EC (PED) “”Pressure equipment directive”

| Pos. | Part name | Material | Standard |

|---|---|---|---|

| 1 | Seat | 1.4301 | EN10088-3 |

| 2 | Lower housing | GJS-400-15 | EN1563 |

| 3 | Plate | 1.4301 | EN10088-3 |

| 4 | “O” ring | FKM | |

| 5 | Plate holder | CW614N | EN12164 |

| 6 | Guide | CW614N | EN12164 |

| 7 | Spring plate | CW614N | EN12164 |

| 8 | Spindle | 1.4301 | EN10088-3 |

| 9 | Spring | SH | EN10270-1 |

| 10 | Upper housing | GJS-400-15 | EN1563 |

| 11 | Lever | ST02Z275 | DIN59232 |

| 12 | Nut | CW614N | EN12164 |

| 13 |

Adjusting screw

|

CW614N | EN12164 |

| 14 | Bonnet | GJS-400-15 | EN1563 |

| 15 | “O” ring | NBR | |

| 16 | Eccentric shaft | 1.4301 | EN10088-3 |

| 17 | Guide nut | CW614N | EN12164 |

| CODE | DN1 | DN1 | L (mm) | L1 (mm) | H (mm) | Diameter | WEIGHT(kg) |

|---|---|---|---|---|---|---|---|

| 030201 | 1/2” | 1/2”, 3/4” | 48 | 49 | 274 | 36 | 2.4 |

| 030202 | 3/4” | 3/4”, 1” | 48 | 49 | 274 | 36 | 2.4 |

| 030203 | 1” | 1”, 1 1/4“ | 63 | 67 | 307 | 50 | 3.2 |

| 030204 | 1 1/4“ | 1 1/4“, 1 1/2“ | 63 | 67 | 307 | 50 | 3.2 |

| 030209 | 1 1/2“ | 1 1/2“ | 63 | 67 | 307 | 60 | 3.3 |