Products

gas and oil installations, MEBA measurings...

Service program

service, calibration, CNC turning, milling...

Sales program

Leser, Danfoss, Bopp&Reuther...

Contact information

SPECIJALNA OPREMA - Lučko d.o.o.

Dolenica 20, Donji Stupnik, 10250 Lučko

ZAGREB, HRVATSKA

POSLOVNA JEDINICA JUŽNA HRVATSKA

Ivana Pavla II 19a, 21212 Kaštel Sućurac,

SPLIT, HRVATSKA

Email: specijalna-oprema@specijalna-oprema.hr

Phone: +385 (0)1 653 0671, +385 (0)1 653 0677

Fax: +385 (0)1 653 0680

The PDF document below provides detailed information for this product

DN 1” - 2”

PN 250

ANSI 1500lb

pmax 210 bar

t -20°C / +90°C

acceptable media natural gas, air, non-aggressive gasses

connections ANSI B1 20.1

APPLICATION

A pilot-operated pressure relief valve SVP-N is a pressure relief valve in which the major relieving device is combined with, and is controlled by, a self-actuated auxiliary pilot.

It’s designed to be used wherever there is a need to exhaust the overpressure volume of gas.

Applications include gas production systems, compressor stations, gas transmission (pipelines) facilities, storage systems, distribution systems and in all types of processing plants.

DESIGN FEATURES

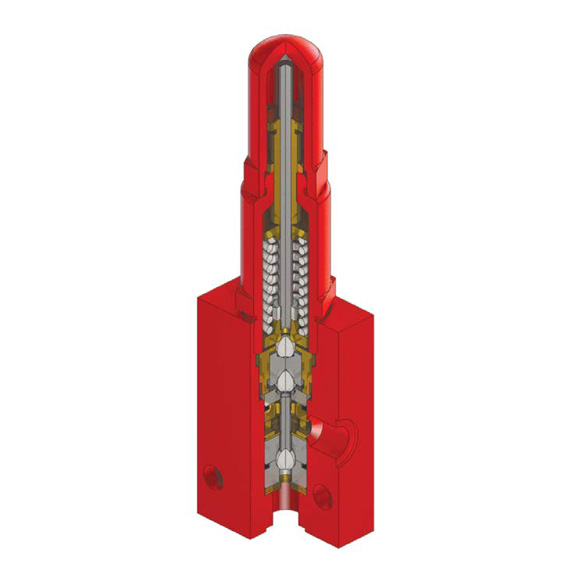

SVN-P soft seat pilot-operated safety relief valves operate on the principle of unequal areas exposed to the same pressure.

When the relief valve is closed, system pressure pushes upwards against the piston seat seal on an area equal to the inside diameter of the seat. Simultaneously, the same system pressure passes through the pilot, exerting a downward force on the piston acting on an area approximately 50% greater than the inside diameter of the seat. The resulting differential force holds the valve tightly closed. As the system pressure rises, the force against the piston seal increases.

When the system pressure reaches the relief valve discharge set pressure , the pilot cuts off system pressure and opens the top of the piston to vent pressure, the pilot valve discharge the chamber of the main valve (releasing pressure) and the main

valve opens completely (h=D).When the predetermined blowdown pressure is reached (93-97,5% of set pressure), the pilot shuts off the exhaust and re-opens the flow of system pressure to the top of the piston with higher pressure value, which

effectively close the relief valve.

Therefore, the basic advantage of the pilot operated safety relief valve is that it, when coming closer to the pre-set discharge pressure, force increases and seat-tightness is better. With the conventional valve it is the opposite – when coming close to the opening pressure, valve starts gradually to release. This valve can be operated in applications with a back pressure ratio of up to 70% which makes it ideal for a non stabile systems.

Flange dimensions can be modified on request to fit most existing installations. This permits SVP-P pilot-operated safety relief valve to be used as replacements for older spring-loaded valves which may not conform to new safety standards

PILOT

This pilot has a fixed blowdown for controlling relief valve opening and closing pressure set points. The opening set pressure is determined by the force of a control spring, which holds the relief control section of the valve closed. When system pressure acting on the relief control valve seat area equals the spring force, the relief line opens, and the blowdown control section closes, blocking system pressure from passing into the chamber above the main valve piston. As the relief line opens, the pressure underneath the control seat is exposed to a larger pressure area which emidiatelly makes the control pilot to quickly reduce pressure in the piston area.

This pressure reduction causes the main valve piston to lift, relieving system pressure. After the system pressure is reduced to a point determined by the control spring, the relief control valve closes, and the open blowdown line valve allows system pressure to re-enter the piston area, forcing the main piston down to a closed valve position.

APPLIED STANDARDS, CODES & DIRECTIVES

ISO 4126-4 “Safety devices for protection against excessive pressure -Pilot operated safety valves”

94/9 EC (ATEX) “Equipment and protective systems intended for use in potentially explosive atmospheres”

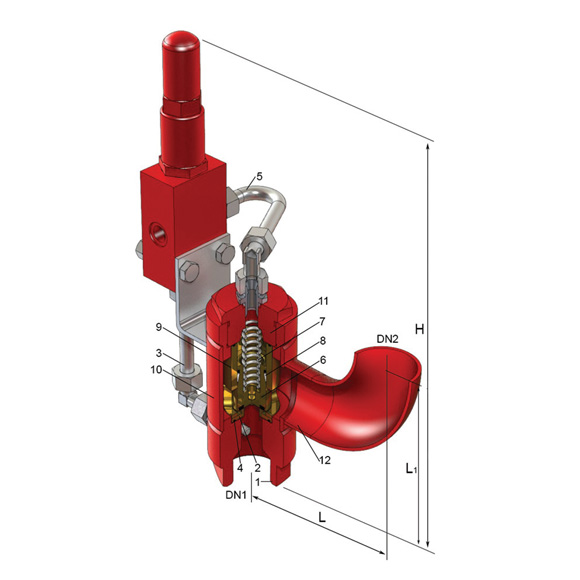

| Pos. | Part name | Material | Standard |

|---|---|---|---|

| 1 | Seat housing | P265GH | EN10273 |

| 2 | Seat | CC333G | EN1982 |

| 3 | Pipe | P235GH | EN10216-2 |

| 4 | “O” ring | NBR | |

| 5 | Pipe | P235GH | EN10216-2 |

| 6 | Piston | CC333G | EN1982 |

| 7 | Spring | 1.4301 | EN10270-3 |

| 8 | Seal | PTFE | |

| 9 | Guide | CC333G | EN1982 |

| 10 | Upper housing | P265GH | EN10273 |

| 11 | Lid | P265GH | EN10028-2 |

| 12 | Pipe | P235GH | EN10216-2 |

| CODE | DN1 | DN2 | L (mm) | L1 (mm) | H (mm) |

set pressure (bar)

|

WEIGHT(kg) |

|---|---|---|---|---|---|---|---|

| 031201 | 1” NPT | 2” | 100 | 228 | 390 | 25 - 210 | 7.5 |

| 031202 | 1 1/2“ NPT | 2” | 100 | 228 | 390 | 25 - 210 | 7.5 |