Products

gas and oil installations, MEBA measurings...

Service program

service, calibration, CNC turning, milling...

Sales program

Leser, Danfoss, Bopp&Reuther...

Contact information

SPECIJALNA OPREMA - Lučko d.o.o.

Dolenica 20, Donji Stupnik, 10250 Lučko

ZAGREB, HRVATSKA

POSLOVNA JEDINICA JUŽNA HRVATSKA

Ivana Pavla II 19a, 21212 Kaštel Sućurac,

SPLIT, HRVATSKA

Email: specijalna-oprema@specijalna-oprema.hr

Phone: +385 (0)1 653 0671, +385 (0)1 653 0677

Fax: +385 (0)1 653 0680

The PDF document below provides detailed information for this product

DN 2” - 10”

class 150, 300lb

pmax 50 bar

t -20°C / +90°C

acceptable media oil, petrol, non-agresive fluids and gases

connections ANSI B 16.5, EN1092, DIN2633-2635

APPLICATION

This type of valve are mostly used in oil and petrol industry and in piping systems for cutting off a flow stream.

Simple and hard design makes it ideal for a outdoor implementation in places where there is a dificulty in frequent maintenance.

DESIGN FEATURES

This valve can be delivered in two type of actuator action:

A- spring closes

The standard implementation where the pneumatic valve acts like an automatic quick-closing valve. Opening is done through solenoid valve (2/3) which leads the instrumental air (gas) into the area under the piston of the actuator. The fast closing is done by the spring.

B – spring opens

The BVK-P valve act as an automatic quick-closing body. The fast closing is done by the spring . Closing is done through an solenoid valve (2/3) which leads the instrumental air (gas) into the area above the piston of the actuator.

Solenoid connection is 1/4”.

ON REQUEST:

- installment of open-close magnetic position sensors

APPLIED STANDARDS, CODES & DIRECTIVES

API 6D “Specification for Pipeline Valves”

API 598 “Valve Inspection and Testing”

ISO 14313 “Petroleum and natural gas industries -Pipeline transportation systems -Pipeline valves”

EN 12266-1 “Industrial valves. Testing of metallic valves. Pressure tests, test procedures and acceptance criteria. Mandatory requirements”

94/9 EC (ATEX) “Equipment and protective systems intended for use in potentially explosive atmospheres”

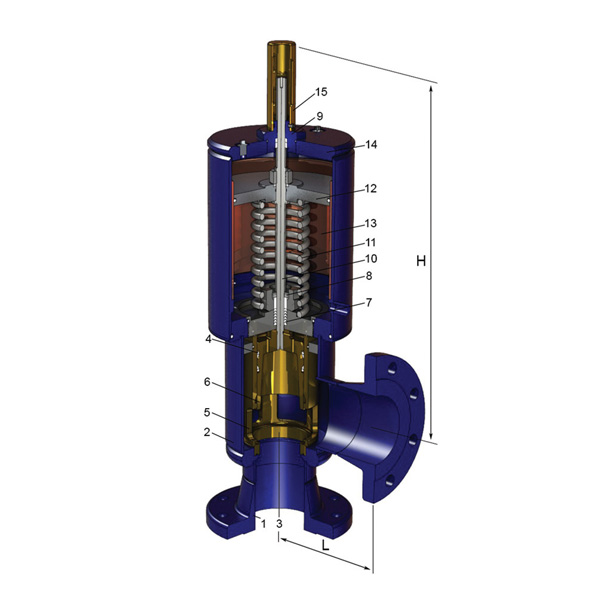

| Pos. | Part name | Material | Standard |

|---|---|---|---|

| 1 |

Connection flange

|

P250GH | EN1092 |

| 2 | Body | P265GH | EN10273 |

| 3 | Seat | CC333G | EN1982 |

| 4 | “O”-ring | FKM | |

| 5 | Cylinder | CC333G | EN1982 |

| 6 | Piston plate | CC333G | EN1982 |

| 7 | Seal | PTFE | |

| 8 | Seal plate | P265GH | EN10273 |

| 9 | Guide bolt | S355 | EN10277-2 |

| 10 | Spindle | 1.4301 | EN10088-3 |

| 11 | Spring | 1.4301 | EN10270-3 |

| 12 | Piston | ENAW6005 | EN573 |

| 13 |

Actuator cylinder

|

S355 | EN10277-2 |

| 14 | Lid | S355 | EN10277-2 |

| 15 | Bonnet | CW614N | EN12164 |

| CODE | DN |

actuator pressure (bar)

|

L (mm) | H (mm) | D (mm) | WEIGHT(kg) |

|---|---|---|---|---|---|---|

| 060601 | 50 (2”) | 1 - 2 | 143 | 517 | 202 (200) | 45 |

| 060602 | 100 (4”) | 1 - 2 | 197 | 553 | 202 (200) | 70 |

| 060603 | 150 (6”) | 1 - 2 | 254 | 746 | 306 (350) | 125 |

| 060604 | 200 (8”) | 1 - 2 | 306 | 779 | 306 (350) | 147 |

| 060605 | 250 (10”) | 1 - 2 | 381 | 739 | 306 (350) | 165 |