Products

gas and oil installations, MEBA measurings...

Service program

service, calibration, CNC turning, milling...

Sales program

Leser, Danfoss, Bopp&Reuther...

Contact information

SPECIJALNA OPREMA - Lučko d.o.o.

Dolenica 20, Donji Stupnik, 10250 Lučko

ZAGREB, HRVATSKA

POSLOVNA JEDINICA JUŽNA HRVATSKA

Ivana Pavla II 19a, 21212 Kaštel Sućurac,

SPLIT, HRVATSKA

Email: specijalna-oprema@specijalna-oprema.hr

Phone: +385 (0)1 653 0671, +385 (0)1 653 0677

Fax: +385 (0)1 653 0680

The PDF document below provides detailed information for this product

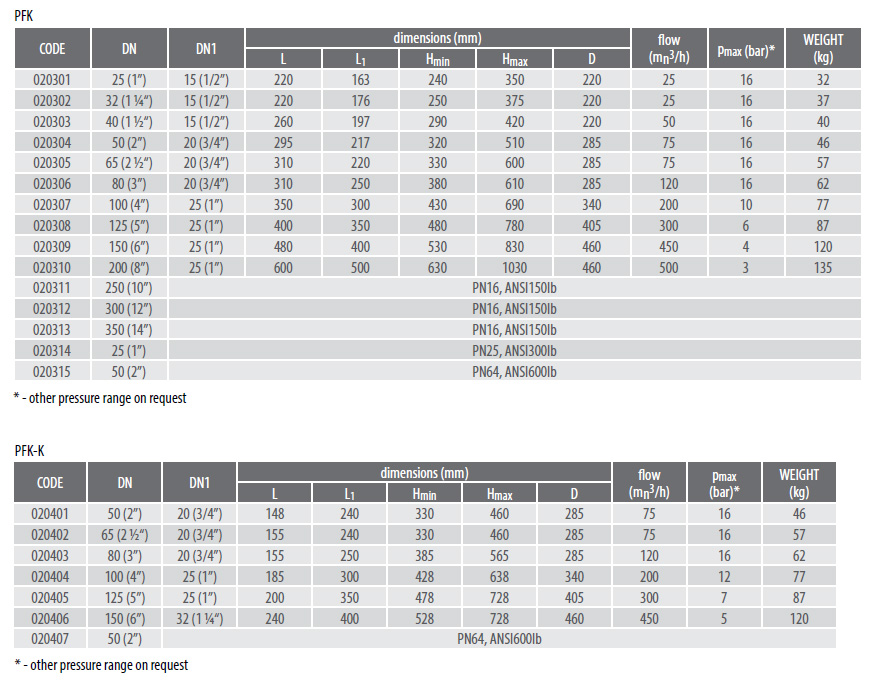

DN 1” – 14” (25 – 350)

PN 16

ANSI 150 lb

pmax 16 bar

medium natural gas, LPG

connections ANSI B.16.5, EN1092

APPLICATION

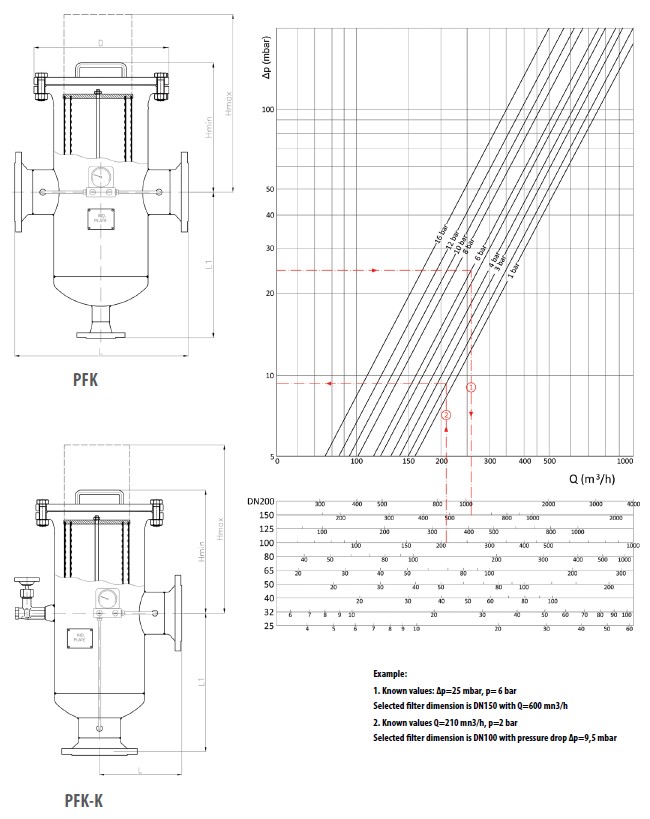

This kind of filter separators are most commonly used in gas reduction stations in the function of separation of solid and liquid particles from the gas. Using the kinetic energy of the gas flow where the velocity increases towards the middle, resulting a reduction of speed of the gas and centrifugal forces at the wall of filter body in this filter separator gas flow prevents particles from accumulating on the walls of the body. Gravity force cancels pressure difference force, which causes particles to fall to the bottom of the filter separator. Filter cartridge can be easily replaced which makes it

DESIGN FEATURES

These filter separators are vertical type, with straight (PFK) and angled (PFK-K) gas connection inlet and outlet.

It is a welded steel construction designed and produced acc. to pressure-vessel directive 97/23/CE. Most commonly it is delivered with differential manometer on which it can be monitored filter cartridge soiling. Filter cartridge can stop particles ≤5μm and is very easy to replace, which makes it ideal for almost continuous working.

Drainage, condensate separation connection can be threaded with ball valve or flange connection, depending on customer request.

ON REQUEST:

- Differential manometer

- ASME certification

APPLIED STANDARDS, CODES & DIRECTIVES

EN 13445 „Unfired pressure vessels“

97/23 EC (PED) “Pressure equipment directive”